Heat resistant solder resist ink(For RPC)

TAINEX HRS-2-6 Series Alkaline development type

Superb onboard-quality in heat-resistance

The product is best suited for applications including on-board substrates where high reliability is required. It features superb heat resistance and thermal cycle resistance.

- Feature High heat resistance:Applicable to 150 deg. C

- Feature Thermal cycle resistance:Endure sharp temperature difference : -65 to 150 deg. C

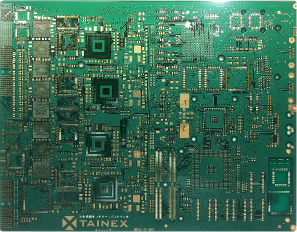

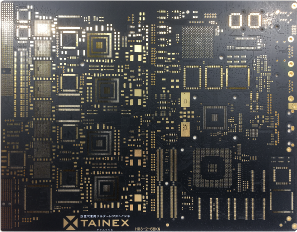

- Feature Color:Available colors: Green & matt black

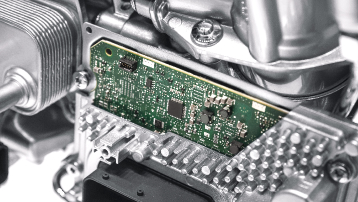

Feature High heat resistance

Different inks were coated on glass boards. The boards were heated at 150℃ for 1000 hours, and the deterioration of the inks caused by the heat was observed.

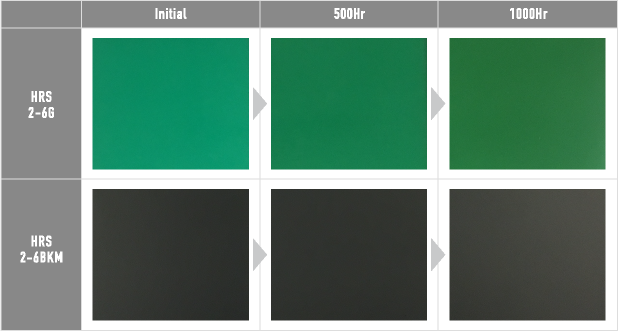

Feature Thermal cycle resistance -65℃⇔150℃ 3000cycle

A substrate was prepared and coated with HRS-2-6G while another substrate was prepared and coated with a general resistor ink. Temperature cycle tests of -65°C for 30 minutes and 150°C for 30 minutes were alternatively executed 3000 times each.

The general resistor ink substrate revealed cracks, but the HRS-2-6G substrate had no cracks, which shows that it strongly performed its intended role as an insulation membrane.

Feature Color

■Coating film performance

| Item | Test method | HRS-2-6G | HRS-2-6BKM |

|---|---|---|---|

| Hardness | JIS K5600-5-4 | 5H | 4H |

| Adhesion | JIS K5600-5-6 | Category 0 | |

| Solvent resistance | Isopropyl alcohol, 5Min immersion at room temp. | OK | |

| Acetone, 5Min immersion at room temp. | OK | ||

| Acid resistance | 10% sulfuric ,30 Min immersion at room temp. | OK | |

| Alkaline resistance | 5% sodium hydrate, 5 Min immersion at room temp. | OK | |

| Solder resistance | JIS C6481 260 deg.C for 20 Sec. | OK | |

| Gold plating resistance |

Electroless nickel gold plating process (Ni:3μm、Au:0.05μm) |

OK | |

| Hear resistance | 150℃×1000Hr | OK | |

| PCT | 121 deg. C for 9 Hr | OK | |

| Combustibleness | UL94 standard | 94V-0 eq. | |

| Radiation factor |

Heat dissipation rate measurement (Measurement range: 3-30 microns) |

85% | |

| Thermal conducton rate | Measurement by thermal conductivity meter | 0.5~0.6W/mK | |

| Total amount of chlorine | Calculated from material used (calculated value) | 440ppm | 310ppm |

| Reflection rate | Measurement by color difference meter | - | Less than 10% |

■Electric characteristics

| Item | Test method | HRS-2-6G | HRS-2-6BKM |

|---|---|---|---|

| Insulation resistance | Initial value | 1.1×1012 | 3.1×1012 |

| 24V load, 85 deg. C, RH85%, 1000Hr | 1.3×1011 | 2.5×1011 | |

| Thermal cycle | (-65 deg. C × 30→150 deg. C × 30Min) × 3000 cycle |

2.9×1011 No defest |

4.3×1011 No defest (1500 times) |

| Surface resistanse | JIS C6481-5-10 | 1.0×1013Ω | |

| Volume resistivity | JIS C6481-5-9 | 1.0×1014Ω・cm | |

| Voltage resistance |

500V×1Min Energization (Measured film thickness 20 microns) |

OK | |

| Relative permittivity | JIS C6481(1MHz) | 3.8 | 3.9 |

| Dielectric tangent | JIS C6481(1MHz) | 0.05 | |

*The results above show reference values, not standard values.