Search by product type

Search by application field

Overview of Okitsumo Paints: To use Okitsumo's Paints correctly and effectively

Appropriate use

brings out proper functions.

Okitsumo's heat resistant and other functional paints have different characteristics. It is necessary to understand them and follow instructions on how to use in order to fully bring out the functions that are best suited for its application and purpose.

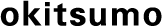

Components of Paint

Paint consists of various types of raw materials that are roughly grouped into components that form the paint film and components that do not form it. The components that form the paint film consist of resin, pigment, and additives; and the other components are solvent.

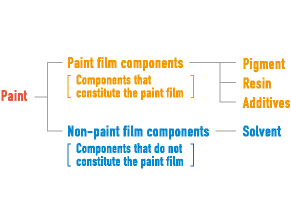

Components of Heat Resistant Paint

With silicon resin as a key ingredient that excels in heat and weather resistance, using metal oxide for pigments will form the robust paint film with heat resistance.

What is Silicon Resin?

Silicon resin is the combination of organic groups, such as methyl and phenyl, and it has the Si-O-Si bone structure very similar to glass. The silicon resin’s organic film is changed to hard inorganic film (similar to ceramics) at around 300°C.

What is Heat Resistant Temperature?

The heat resistant temperature of each paint is determined by the overall performance of adhesion, anticorrosion, and resistance to discoloration etc.

Heat Resistance of Materials to be Painted

In general, ordinary steel plates are used as materials to be painted. Recently, plated steels, aluminum, and stainless steel have often been used. However, the materials themselves have thermal limits.

| Ordinal Steel Plates | Up to 600°C |

|---|---|

| Hot Dip Galvanized Steel Plates | Up to 400°C |

| Electrogalvanized Steel Plates | Up to 200°C |

| Aluminized Steel Plates | 400°C to 500°C |

|---|---|

| Aluminum | Up to 500°C |

| Stainless steel | Up to 800°C |

| *Chemical Film | Up to 300°C |

The above shows general heat resistant properties of each material.

There are some products that cannot be applied on these materials. Please check applicable materials on each product's specification.

Types of Surface Treatment

Contaminations, such as oil, dust, and dirt, adhere to the material during the formation process. Before painting, the material must be cleaned by removing such adherents.

| Physical Surface Treatment | |

|---|---|

| Blasting | A method that uses the rust removing device (blast machine) to blow river sand or silica sand onto the surface at a high pressure. |

| Power tools | A method used to scrape off the rust from the surface by using a sander or a grinder. |

| Hand tools | A method used to scrape off the rust by hand by using a wire brush or sandpaper. |

| Chemical Surface Treatment | |

|---|---|

| Degreasing | A method used to remove oil by solvent cleaning and a degreasing agent. |

| Removal of rust | A method used to remove rust by using strong acid. This is also called pickling. |

| Surface adjustment | Adjusting the surface so that the chemical film forms equally on the surface. |

| Chemical treatment | Form a phosphoric acid zinc film to increase the corrosion resistance and adhesion. |

Level of Surface Treatment

The surface treatment is one of the important processes that greatly affect the film life.

| Types of Keren | Processing Method | Surface Adjustment | Related Standard | |

|---|---|---|---|---|

| SSPC standard (U.S.A) |

SIS standard (Sweden) |

|||

| 1st class surface preparation | Blasting | Removes the old paint film and rust completely, and finishes it in ash gray. | SSPC-SP5 SSPC-SP10 |

SIS Sa3 SIS Sa2 1/2 |

| Acid Wash | Completely eliminates black skin and rust. | SSPC-SP8 | ||

| 2nd class surface preparation | Power Tools (Hand Tools) |

Removes the old paint film and rust to uncover the steel surface. If the normal paint is present, roughen the surface. | SSPC-SP3 | SIS St3 |

| 3rd class surface preparation | Power Tools (Hand Tools) |

Removes the deteriorated paint film by using the tools on the whole surface, and scrapes the rust to uncover the steel surface. | SSPC-SP2 | SIS St2 |

Painting

Okitsumo's products can be treated in the same way as in a general painting work. It is also possible to do electrostatic coating as long as you are careful about the thinner's electrostatic property and dryness. Because some of products include large amounts of metal pigments, please mix thoroughly before application.

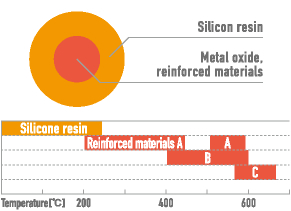

Film Thickness and Initial Heating

The film thickness is a very important factor because it determines whether the heat resistance, appearance, and anticorrosion can be maintained for a long period of time. The standard film thickness is very important because it brings out the highest performance of paint. The initial heating should be done gradually. When the standard film thickness is exceeded and heat-up is done rapidly, the residual solvent and the reactive gas are produced in large amount during the hardening of the paint film, which degrade the performance, such as peeling caused by the swelling of the paint film.

Selection of Paints

Please select the appropriate paint according to the object's temperature conditions and the required functions. Or please feel free to contact us as we can select the appropriate paint according to the information that you give us, such as purpose, color, gloss, paint type, baking condition, heat resistant temperature, material, surface treatment, painting method, volume, and the required performance.

Handling Precautions

- Store the paint indoors in a well-ventilated place in accordance with the related laws and regulations.

- Do not use the paint where there is a possibility of fire.

- During painting and drying, make sure that the place is well ventilated and avoid inhaling steam or gas.

- If you have stored the paint for a long period of time, hard sediments appear in the paint even though the lid is completely sealed.

- Please mix thoroughly before use.

- If the paint container expands by any chance, please contact us.

*The paints described in this document are designed and manufactured for general industry, and they shall not be used for medical/dental equipment and items or their parts that may contact living tissue or body fluid, regardless of whether it is temporally or permanently.