OurTechnology: #3Development Story #01

Paint with heat resistance of 200°C and low heat conductivity of 45 mW/m・K

Heat Insulation and Retention Paint HIP AERO

Since its release in November 2015, the HIP AERO, heat insulation paint for facilities, has been widely adopted with the expectation of reducing heat loss and reducing the expenses for fuel or electricity required for heating. The following is the story of the development of the HIP AERO.

Osamu Ura, Environmental Product Development Section, Engineering Department, Paint Division

Meeting with Aerogel, Struggle for Lightness

Thermal conductivity is a measure of the extent to which heat can be conducted. As this value decreases, heat conduction becomes more difficult, which leads to heat insulation. Therefore, in order to manufacture excellent insulation paint, it is necessary to mix the paint with as much low thermal conductivity material as possible.

Although gases offer excellent heat insulation because of the lower thermal conductivity compared to liquids and solids, gases cannot remain in the same place because they are fluid. If there is a difference in temperature, gases move by convection, which transfers the heat. To prevent convection, it is necessary to make the gas to remain in the same place. Because the paint is liquid, it is not possible to keep air in the paint. Therefore, the heat insulation material for paint was generally a hollow balloon. Low thermal conductivity was achieved by mixing the paint with many hollow balloons with air. However, the hollow balloons require a solid shell to confine the air and prevent breakage. This shell has high thermal conductance, which cannot fully use air with low thermal conductivity. Although our company developed and sold heat insulation paint, we were unable to provide sufficiently satisfactory products for customers who required higher performance because there was a limitation in thermal conductivity for paints and coating films in the design of the hollow balloons.

In order to make higher performance heat insulation paint, it was necessary to select material with lower thermal conductivity and lighter weight than those of a hollow balloon.

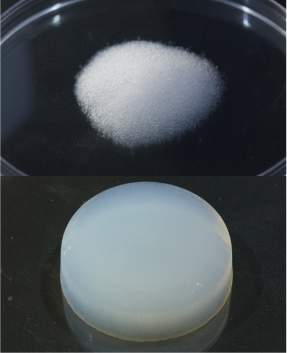

Difficulty with Heat Insulation

As a result of investigations of different types of materials, we discovered the aerogel. Aerogel is made by removing solvent from gel, as its name suggests. It is similar to koyadofu made by freezing bean curd to remove the liquid. Aerogel is an extremely light porous structure where 95% of the total weight is air. The thermal conductivity is 17 mW/m・K, the lowest of all solids, because of the large volumes of air. It also supersedes the hollow balloon, so we thought it was possible to develop a paint with higher heat insulation by using aerogel. In addition, we found that aerogel was likely to provide stable performance because of its structure in which air is stored in the highly fine mesh, which slightly increases thermal conductivity even when some of the mesh is broken to eliminate some air. Aerogel is an ideal heat insulation material.

Although light weight is an essential factor in manufacturing paint with high heat insulation, the major obstacle was to apply the aerogel to paint. Paint is a composite of different materials and includes resin that makes up the framework of the paint, pigment for coloration and heat insulation, and solvent that evaporates. Failing to mix those materials uniformly disables the formation of an ideal coating film, which results in various defects. Aerogel is an extremely light material with a density one-tenth of water. It is like trying to immerse a balloon in water. In fact, we conducted many experiments to stably and uniformly inject aerogel into water. In the initial stage, injecting aerogel while agitating failed to mix the aerogel, it just kept circulating in the water. Once aerogel was mixed, when the agitation was stopped, it floated on the water. After that, we realized the stable test production and the factory production by adjusting different factors, such as the compound ratio, paint viscosity, manufacturing procedure, pH, number of rotations, and operation time. Finally, we commercialized HIP AERO heat insulation and retention paint with thermal conductivity of 45 mW/m・K, one-third that of conventional paint, which enables thick coating of up to 0.5 mm for one-time painting.

Heat insulation and retention for use below freezing and suppression of condensation

After HIP AERO was available for sale, different users considered the paint and verified the effect after actual use. It was reported that painting HIP on the surface of the furnace where oil and gas burned decreased the surface temperature, which decreased the risk of burning in contact with it and reduced the heat to improve the working environment.

Some factories may handle high temperatures and low temperatures. One of the problems of low temperatures is condensation. Many water droplets are generated on large tanks and pipes, which adversely affects the facilities or work environment. If a water droplet drops onto the floor, the floor may become slippery or may become moldy. Whether such a phenomenon can be mitigated by painting HIP AERO with heat insulation is considered in new fields not related to heat resistance.

We hope that HIP AERO will more greatly contribute to society.

ARCIVESDevelopment Story Past articles

- #01

- Heat Insulation and Retention Paint HIP AERO

- 2015.10.14 update

- #02

- Okitsumo MCF Coating

- 2016.07.00 update