Heat resistant solder resist ink(For RPC)

TAINEX HRS-1-8W White Alkaline development type

Whiteness which beats heat-related problems

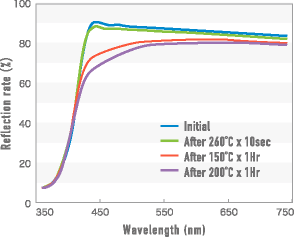

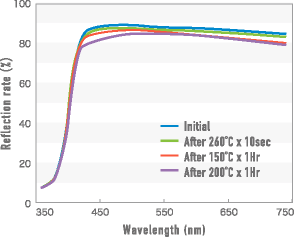

- Feature High heat resistance:Deterioration in reflectance after the heat-resistance treatment can be kept to a minimum

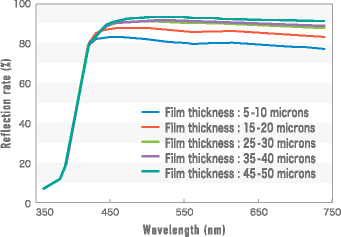

- Feature High light reflection:With a film thickness of 45 microns or more, 90% reflectance can be achieved.

- Feature Gold plating resistance:The resistor ink remains nearly free from discoloration even if it is heated after gold plate processing.

Feature High heat resistance

Film thickness:17~20 microns Mesurement : On copper

| Product Name |

Reflection rate (450nm) |

L | a | b |

|---|---|---|---|---|

| Initial value | 90.4 | 94.8 | -1.8 | 1.0 |

| 150℃×10Hr | 75.2 | 91.6 | -2.1 | 8.3 |

| 260℃×10sec | 88.0 | 94.1 | -2.0 | 1.3 |

| 200℃×1Hr | 69.8 | 90.8 | -2.2 | 9.9 |

| Product Name |

Reflection rate (450nm) |

L | a | b |

|---|---|---|---|---|

| Initial value | 87.0 | 93.9 | -1.8 | -0.2 |

| 150℃×10Hr | 84.8 | 93.2 | -2.5 | 0.1 |

| 260℃×10sec | 85.8 | 93.7 | -2.1 | 0.4 |

| 200℃×1Hr | 83.1 | 93.2 | -2.8 | 2.5 |

After the reliability test at 150°C for 10 hours wherein mounting of COB is assumed, 8W retains a reflectance of 84.8%, while the conventional product remains at 75.2%.

Feature High light reflection

With a film thickness of 45 microns or more, 90% reflectance can be achieved.

| Film thickness |

Reflection rate (450nm) |

L | a | b |

|---|---|---|---|---|

| 5~10μm | 77.0 | 88.4 | -1.2 | -2.5 |

| 15~20μm | 87.0 | 93.9 | -1.8 | -0.2 |

| 25~30μm | 89.2 | 95.9 | -2.0 | 1.9 |

| 35~40μm | 89.9 | 96.5 | -2.0 | 2.5 |

| 45~50μm | 90.7 | 97.1 | -1.9 | 3.0 |

Feature Gold plating resistance

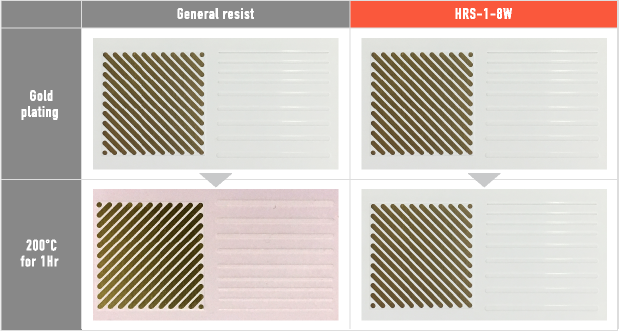

--- A substrate was prepared and coated with HRS-1-8W on one side and a general resistor ink was coated on the other side, and gold plating was applied on both sides. Thereafter, they were heated at 200℃ for one hour, and the discoloration degrees of the resistor inks were compared. ---

The side with the general resistor ink changed to a pink color as the heat was applied and the reflectance deteriorated. On the other hand, 8W did not change in color and showed no deterioration in reflectance. This means 8W is capable of retaining high reflectance.

■Coating film performance

| Item | Test method | HRS-1-8W |

|---|---|---|

| Hardness | JIS K5600-5-4 | 5H |

| Adhesion | JIS K5600-5-6 | Category 0 |

| Solvent resistance | Isopropyl alcohol, 5Min immersion at room temp. | OK |

| Acetone, 5Min immersion at room temp. | OK | |

| Acid resistance | 10% sulfuric ,30 Min immersion at room temp. | OK |

| Alkaline resistance | 5% sodium hydrate, 5 Min immersion at room temp. | OK |

| Solder resistance | JIS C6481 260 deg.C for 20 Sec. | OK |

| Gold plating resistance |

Electroless nickel gold plating process (Ni:3μm、Au:0.05μm |

OK |

| Hear resistance | 150℃×1000Hr | OK |

| PCT | 121 deg. C for 9 Hr | OK |

| Combustibleness | UL standard | 94V-0 eq. |

| Radiation factor |

Heat dissipation rate measurement (Measurement range: 3-30 microns) |

75-85% |

| Total amount of chlorine | Calculated from material used (calculated value) | Less than 100ppm |

| Amount of sulfur | Calculated from material used (calculated value) | None contain |

■Electric characteristics

| Item | Test method | HRS-1-8W |

|---|---|---|

| Insulation resistance | Initial value | 3.8 × 1012 |

| 24V load, 60 deg. C, RH90%, 1000Hr | 1.0×1012 | |

| Surface resistanse | JIS C6481-5-10 | 1.0×1013Ω |

| Volume resistivity | JIS C6481-5-9 | 1.0×1014Ω・cm |

| Voltage resistance |

500V×1Min energization (Measured film thickness 20 microns) |

OK |

| Relative permittivity | JIS C6481(1MHz) | Evaluating |

| Dielectric tangent | JIS C6481(1MHz) | Evaluating |

*The results above show reference values, not standard values.