Heat Insulation Paint HIP AERO

A coating is the only method that enables thermal- insulate any shapes.

- Feature It enables to heat insulate the complex shaped equipment because it is a coating material.

- Feature It protects the steel from being rusted from the condensation.

- Feature It visualizes the corroded area of equipment that used to be difficult with the ordinary heat insulation materials.

Feature It enables to heat insulate the complex shaped equipment because it is a coating material.

For example,

- where it is difficult to use the insulation material on pipes in the narrow and small area.

- where it is difficult to wrap the insulation material around the doors or lids.

- where it is difficult to wrap the insulation material because they are curved equipment.

□ Actual cases ① :Steam pipe (Chemical manufacturer)

Before

Customer's problem

The surface of many steam pipes reached over 80℃. Unable to cover the whole pipes with the insulation materials for their complex shapes and the concern to get burnt in the work of using the materials.

After

Customer's voice

The pipes could get insulated no matter what shapes they were and I'm satisfied with the effect.

The surface temp. has downed 20℃. Now we can touch the surface for several seconds without any burn injury.

□ Actual cases ② :Water reserve tank (Confectionery company)

Before

Customer's problem

Since the water reserve tank and the boiler facilities were installed in the same area, it caused the water temp. to rise. I had given up the idea of using the heat insulation material because it could cause the fibrous dust from the insulation materials.

After

Customer's voice

Significantly decreased the number of cooling procedures in summer: it used to be daily.

Now so far it is only 3 times throughout the season.

It does not cause the fibrous dust either and I'm satisfied with the effect.

Feature It protects the steel from being rusted from the condensation.

For example,

- When you like to do something against the corrosion of equipment due to the dew condensation.

- When you think it might be a good idea but it is nothing serious yet to have a thermal insulation work done.

- When you like to add the countermeasure against the dew condensation on the pipes applied with anticorrosion film.

□ Actual cases ③ :Condenser (Confectionery company)

Before

Customer's problem

In summer, dew condensation on the surface of the condenser and water drops were collected in a vessel under it. We also had a trouble of mold grown on the surface of the facility by water drops.

After

Customer's voice

Not only we could reduce the times to dump the water, but we could prevent the mold from growing. I'm also very satisfied with the sanitary condition improved.

Feature It visualizes the corroded area of equipment that used to be difficult with the ordinary heat insulation materials.

For example,

- When you easily want to check the corrosion level of equipment under the insulation material.

□ Actual cases ④ :Pipes for outdoor (Steel manufacturer)

Before

Customer's problem

Though an outside pipe were wrapped with an insulation material, the pipe was corroded without being noticed due to the rain entered the insulation material. We don't want to miss such corrosion under the insulation.

After

Customer's voice

The pipe can be insulated without any gaps by the coating. I'm very satisfied that I can check the corrosion of a pipe even if the coating were peeled off by any incidents.

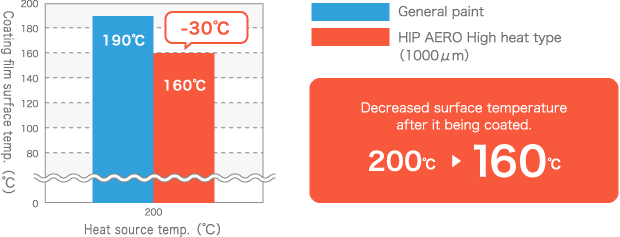

■ Although it is a coating material, HIP AERO has a superior heat insulation performance

□ The changes of surface temperature when applied HIP AERO.

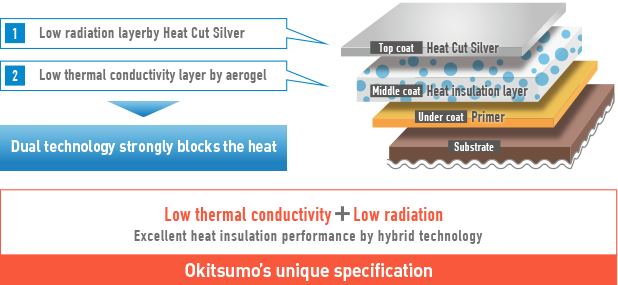

□ Thermal insulation properties of HIP AERO ① : Dual heat insulation mechanism in only HIP AERO

Heat transfer is suppressed by aerogel and heat release is limited by heat cut silver’s low-emissivity,

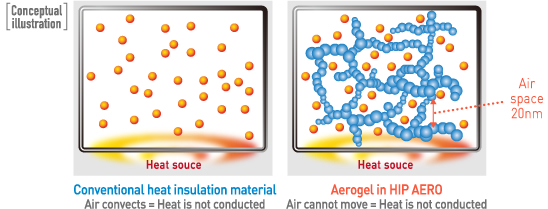

□ Thermal insulation properties of HIP AERO ② :What is Aerogel?

Aerogel is made from silica, which has low heat conductivity, and 95% of the total is super porous fine structure. Because the micropore diameter of the super porous fine structure is smaller than the mean free path of air, aerogel suppresses the heat conductivity by convection and realizes a totally new heat insulation. It is the most advanced material that is even applied in space development by NASA.

Expanding applications and capabilities.

- Every kind of industrial furnace (ex. cure ovens・holding furnaces etc.)

- Heat exchanger

- Kiln

- Heating/Cooling tanks

- Various pipes

■Volume (Package)

Okitsumo’s environmental contribution

ReEner, Energy-Efficient and Environmentally Conscious Product Line

ReEner is an energy-efficient and environmentally conscious product line developed with the concept Energy-Saving and Energy-Creating Paint via Photothermal Control. As a manufacturer of heat resistant and functional paints, Okitsumo makes a proposal for the environmental solution.

Product search

Product search

Category Search

-

Search by product type

-

Search by application field

- Product lineup

- TDS