Lubricant Paint THERMO LUB

Okitsumo's Dry Lubricant Coating

Excellent heat resistant lubricant paint for metal and rubber. A wide range of products for dry lubrication for any application.

- Feature For high-temperature or low-temperature atmospheres or vacuums where liquid lubrication such as oil cannot be used.

- Feature For parts or work areas that are sensitive to stickiness of oil or grease.

- Feature For parts that are sensitive to volatile component of oil or grease.

- Feature Lower friction enabling miniaturization and lightweight of parts.

- Feature Longer service life and maintenance-free of parts

Dry lubrication displacing oil lubrication

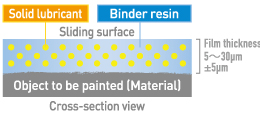

Dry lubrication is a film formed by combining a solid lubricant agent, such as fluorine and molybdenum, with resin and is called a dry lubricating film. Dry lubrication is widely used in vacuum or high-temperature atmospheres where liquid lubrication such as oil cannot be used or for parts that are sensitive to sticking.

Advantages of dry lubricating film

- Functionality realized even under high-temperature, low-temperature, or vacuum state

- Maintenance-free providing reduction of working hours

- Oil-free lubrication realizing non-adhesive clean workability

Lineup

■Heat Resistant Lubricant Paint THERMO LUB (For Metal)

- Focusing attention on the excellent performance of fluorine resin as a solid lubricant, the combination with organic or inorganic polymers has realized low-temperature firing of a paint film that is excellent in low friction coefficient, non-stickiness, and corrosion resistance as in fluorine resin paint.

- Heat resistant lubricant THERMO LUB (for metal), designed with sufficient consideration for workability, also improves productivity.

Feature

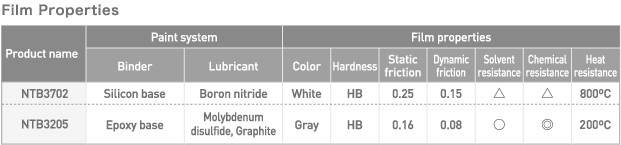

Forced baking Resistance / High Heat Resistance

- This paint contains a solid lubricant (nitride boron, molybdenum disulfide, graphite) and is especially suitable for prevention of burning and jamming under high heat environments. *NTB3702: Excellent heat resistance and suitable for high heat environments. *NTB3702: Excellent load bearing and suitable under extreme pressure.

Expanding applications and capabilities.

- Gasket

Abrasion Resistance / Heat Resistance

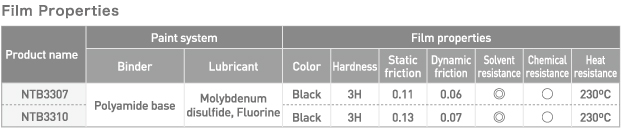

- This paint uses the polyamide-based special binder and offers excellent abrasion resistance and low frictional properties owing to molybdenum disulfide and fluorine.

- Resistant to almost all solvents.

- It has good chemical resistance and is excellent in acid resistance.

Expanding applications and capabilities.

- NTB3307 : Plunger, compressor parts

- NTB3310 : Motor parts

Forced baking Resistance / Load Bearing

- The large amount of solid lubricant of molybdenum disulfide and graphite makes it suitable for prevention of burning and jamming.

- Suitable under extreme pressure because of the excellent load bearing property.

Expanding applications and capabilities.

- Plunger

- Gasket

- Compressor parts

Low abrasion / Heat Resistance and Processing Resistance

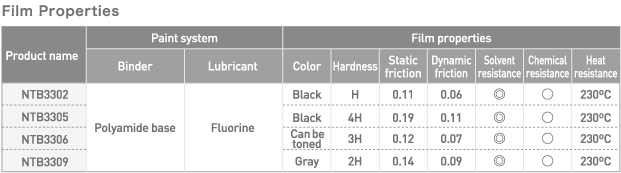

- This paint uses the polyamide-based special binder and is excellent in low frictional properties owing to fluorine.

- Resistant to almost all solvents.

- Offers good chemical resistance and excellent acid resistance.

Expanding applications and capabilities.

- NTB3302 : Camera parts

- NTB3305 : Escalator parts

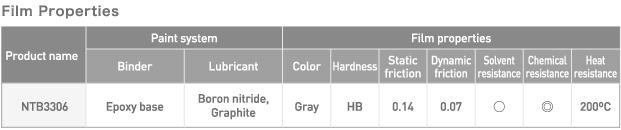

- NTB3306 : Chip saw

- NTB3309 : Metallic bush

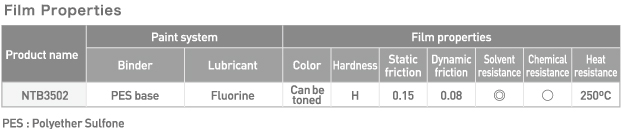

Nonadherence / Heat Resistance

- Excellent non-stickiness owing to fluorine and effective in the prevention of adhesion of dirt. Also, offers excellent low frictional properties.

- Offers excellent solvent resistance and good chemical resistance.

Expanding applications and capabilities.

- Water coupler

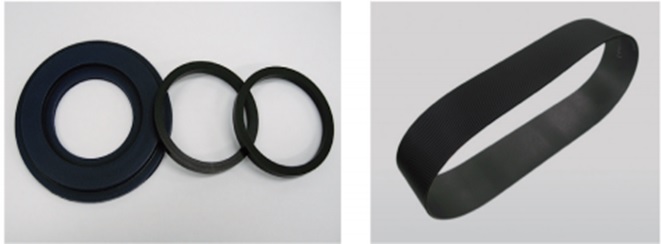

■Heat Resistant Lubricant Paint THERMO LUB (For Rubber)

- Possible to coat natural rubber and EPDM.

- This paint prevents adhesion by decreasing the friction coefficient of the rubber surface.

- Expansion and contraction of rubber does not cause the paint film to peel or crack.

Feature

Abrasion Resistance / Low Friction

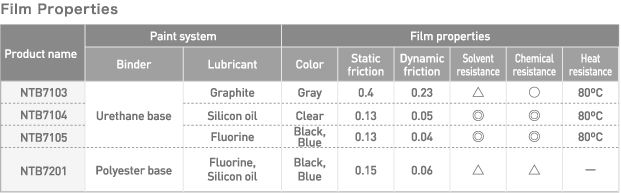

- NTB7103 An air drying paint film that contains a large amount of graphite.

- NTB7104 This can adhere to EPDM. Offers good resistance to abrasion, friction, chemicals, and solvents.

- NTB7105:provides good low abrasion properties and resistance to chemicals and solvents.

- NTB7201:Painting is possible just after the vulcanization process.

※NTB7105 blue has been discontinued.

Expanding applications and capabilities.

- NTB7103 : Window cleaning rubber

- NTB7104 : O-ring

- NTB7105 : Hand brake cover, O-ring

- NTB7201 : Sash parts

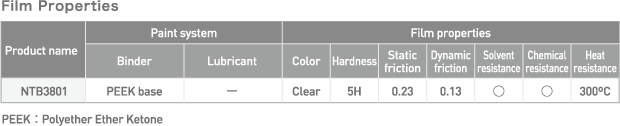

■Heat Resistant Lubricant Paint THERMO LUB (PEEK-COATING)

- VICTREX in U.K. THERMO LUB (PEEK-COATING) mainly consists of PEEK resin for an extension of the service life of parts and improvement of abrasion resistance in the applications of automobiles, industrial equipment, and electronic devices.

- This coating agent allows thin-film processing (20 μm to 100 μm) for PEEK resin while maintaining performance.

- This is a water-based dispersion type in consideration for environment.

- This provides metal material with chemical resistance, abrasion resistance, and insulation properties.

Expanding applications and capabilities.

- Chip saw

■Volume (Package)

| Product Name |

Specification | Heatproof Temperature |

Binder | Lubricant Agent |

No. | Color | Package |

|---|---|---|---|---|---|---|---|

| Lubricant Paint THERMO LUB (for Metal) |

Solvent Base |

800℃ | Silicon Base |

Nitride Boron |

NTB3702 | White | Solvent Base: 1kg,4kg,16kg Water Base:1kg,10kg |

| 500℃ | Epoxy Base |

Molybdenum Disulfide Graphite |

NTB3205 | Grey | |||

| 200℃ | NTB3206 | Grey | |||||

| 230℃ | Polyamide Base |

Molybdenum Disulfide, Fluorine |

NTB3307 | Black | |||

| 230℃ | NTB3310 | Black | |||||

| 230℃ | Fluorine | NTB3302 | Black | ||||

| Water Base | 230℃ | NTB3305 | Black | ||||

| Solvent Base |

230℃ | NTB3306 | Can be toned |

||||

| 230℃ | NTB3309 | Grey | |||||

| 200℃ | Epoxy Base |

NTB3201 | Black | ||||

| 200℃ | NTB3202 | Black | |||||

| 200℃ | NTB3203 | Black | |||||

| 200℃ | Acrylic Base | NTB3101 | Can be toned |

||||

| 250℃ | PES Base | NTB3502 | Can be toned |

| Product Name |

Specification | Heatproof Temperature |

Binder | Lubricant Agent |

No. | Color | Package |

|---|---|---|---|---|---|---|---|

| Lubricant Paint THERMO LUB (For Rubber) |

Solvent Base | 80℃ | Urethane Base |

Graphite | NTB7103 | Gray | 800g・3kg |

| Water Base | Silicone Oil | NTB7104 | Clear | 1kg,10kg | |||

| Fluorine | NTB7105 | Black | |||||

| - | |||||||

| - | Polyester Base |

Fluorine, Silicon Oil |

NTB7201 | Black | |||

| Blue |

| Product Name |

Specification | Heatproof Temperature |

Binder | Lubricant Agent |

No. | Color | Package |

|---|---|---|---|---|---|---|---|

| Lubricant Paint THERMO LUB (PEEK-COATING) |

Water Base | 300℃ | PEEK Base |

- | NTB3801 | Clear | 0.5kg,8kg |