Heat Resistant Mold Release Lubricant Heat Resistant Mold Release Lubricant

Power of Heat Resistant Mold Release Lubricant

Easily obtain the excellent performances: abrasion resistance, lubricity, and heat resistance. A wide lineup of boron nitride, fluorine, and molybdenum will solve many different types of problems on-site.

- Feature Being aerosol, it is easy to use.

- Feature Several series are available, which allow you to choose among them depending on the application and purpose.

- Feature Sufficient lubricating performance.

Combination of different types of solid lubricants and binders will produce a wide range of performances.

Lineup

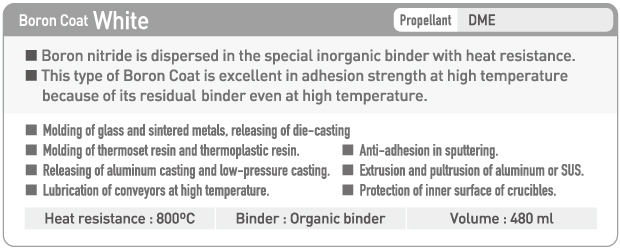

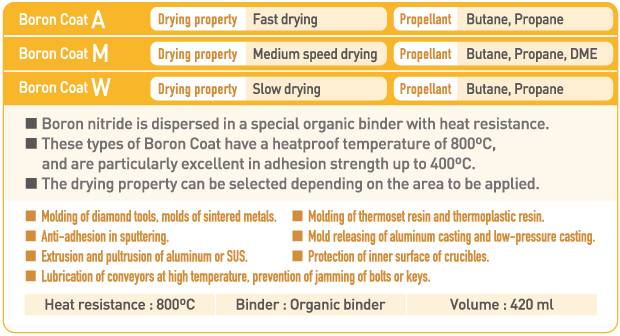

■Boron Coat Series

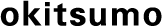

●Excellent Properties of Boron Nitride (Hexagonal Boron Nitride)

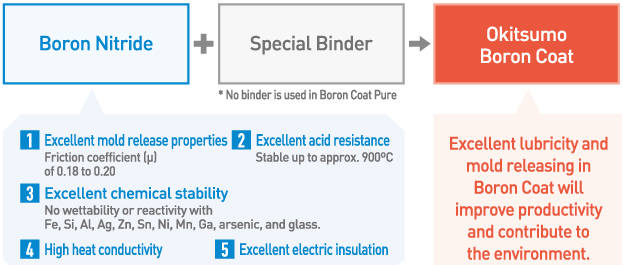

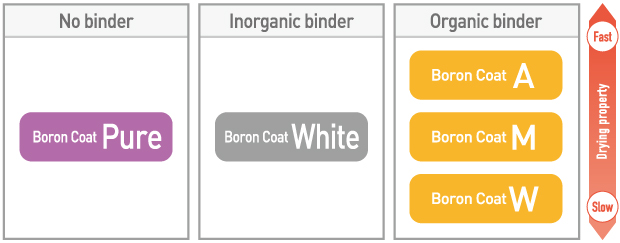

●Boron Coat Lineup

Strong, rapid, smooth in various scenes.

Expanding applications and capabilities.

- [Mold Release] Prevention of burning of casting die, sintered metal forming (hot press), diamond tool forming, and high-temperature bolt

- [Lubrication] Prevention of jam of bolt or bearing, and providing lubricity under high temperature.

■Graphite Coat Series

| Graphite Coat |

|---|

| ●This provides the film containing high-density black lead, and is excellent in mold release stability. |

Expanding applications and capabilities.

- [Mold Release] Prevention of burning of casting die, sintered metal forming (hot press), diamond tool forming, and high-temperature bolts

- [Lubrication] Prevention of jam of bolt or bearing, and providing lubricity under high temperature.

■Fluorine Coat Series

| Fluorine Coat A |

|---|

| ●This is a dry type of lubricating spray that disperses the fluorine resin in the heat resistant binder. |

| Fluorine Coat B |

|---|

| ●This is a wet type spray that realizes to the maximum extent the mold release specific to fluorine resin. |

Expanding applications and capabilities.

- Providing lubricity for fastener or shutter

- Prevention of squeaks and other noise

■Molybdenum Coat Series

| Molybdenum Coat |

|---|

| ●This provides an excellent lubricating film with lamellar crystal of molybdenum disulfide. |

Expanding applications and capabilities.

- Providing lubricity for portions that are sensitive to oil and fat content, and providing lubricity for portions that are difficult to lubricate (long-term lubrication)

■Talc Coat Series

| Talc Coat |

|---|

| ●Fine particles of talc (talcum) are dispersed in the inorganic binder. |

Expanding applications and capabilities.

- Casting dies of aluminum, zinc, and tin

■Volume (Package)

| Product Name |

Heatproof Temperature |

Solid Lubricant |

Color | Package | ||

|---|---|---|---|---|---|---|

| Heat Resistant Mold Release Lubricant |

Boron Coat | Pure | 800℃ | Boron Nitride | White | 420ml |

| White | 100ml,480ml | |||||

| A | 420ml | |||||

| M | ||||||

| W | ||||||

| Graphite Coat |

450℃ | Black Lead |

Black | |||

| Fluorine Coat |

A | 260℃ | Fluorine | White | ||

| B | Clear | |||||

| Molybdenum Coat |

350℃ | Molybdenum Disulfide |

Black | |||

| Talc Coat | Lubricity:150 Mold Releasing:800 |

Talc | White | |||